Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

On-Site Field Thermal Spray Coating Services

For jobs that are too large or too time-sensitive to ship, Hayden can deploy a team of technicians and hardware to provide coating services in the field

Our Field Team will Come to You

Our Focus is on quality and flexibility

For jobs that are too large or too time-sensitive to ship, Hayden can deploy a team of technicians and hardware to provide coating services in the field, at nearly any facility with efficiency thanks to our mobile technicians using field management systems to deploy technicians and hardware, as well as keep us up-to-date on the progress of the work order.

Thermal spray equipment, as well as custom tooling and fixtures designed to speed setup and tear-down, is available for rapid shipment, either by container or in one of our trucks to your location.

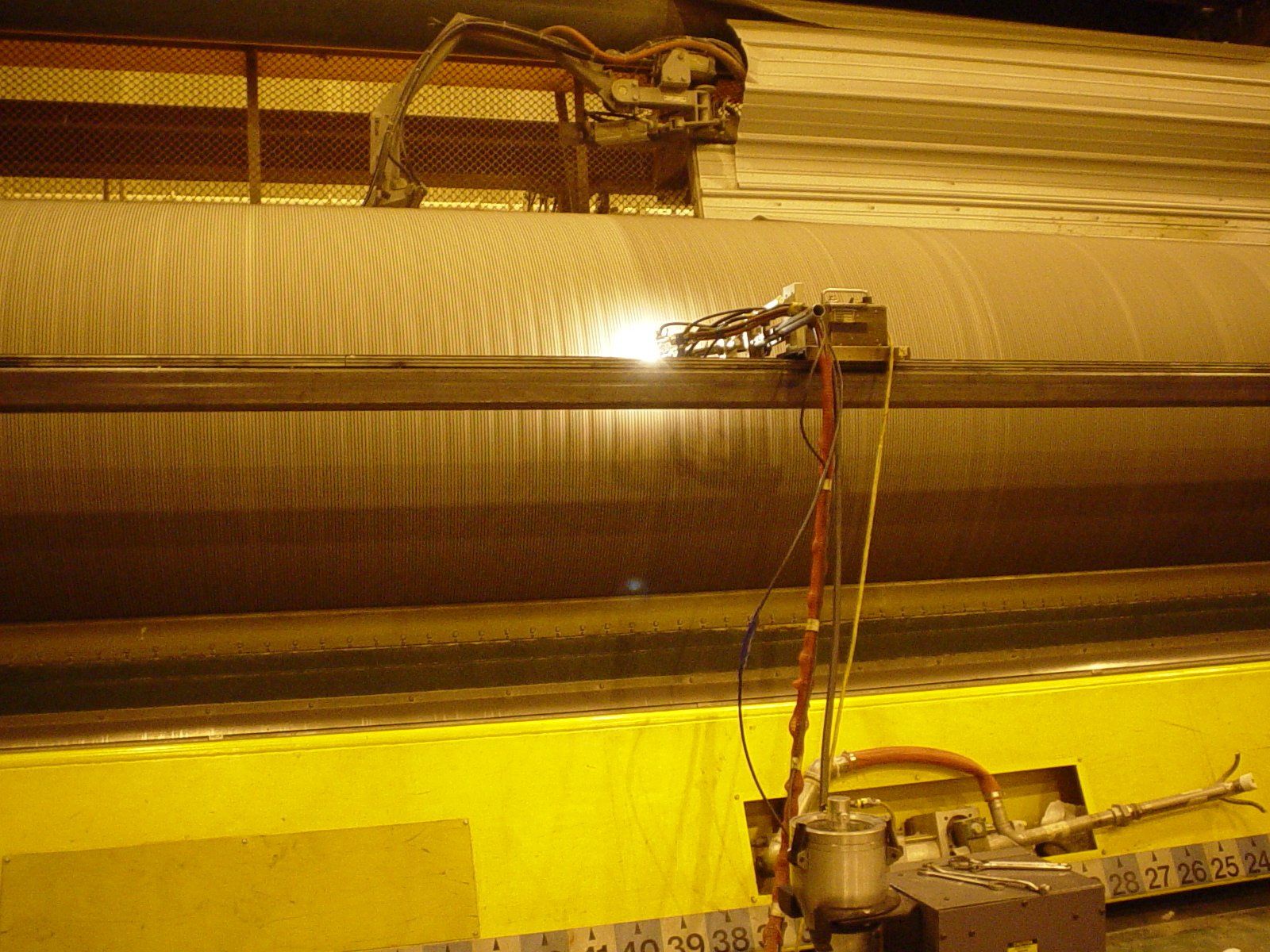

Roll Resurfacing

- HC Traction Coating available in four textures for friction control

- Release Coatings over traction; samples available upon request

- Blast Cleaning to reprofile surface finish

- Hayden Technician provides monitoring of coating surface to ensure maximum performance

Machine Element Repair

Hayden field teams regularly perform on-site surface restoration for large components in mission-critical applications in order to get machinery back in operation quickly with minimal disassembly. Hayden specializes in repair of shafts used in power generation. Application of refractory alloys on furnace shells.

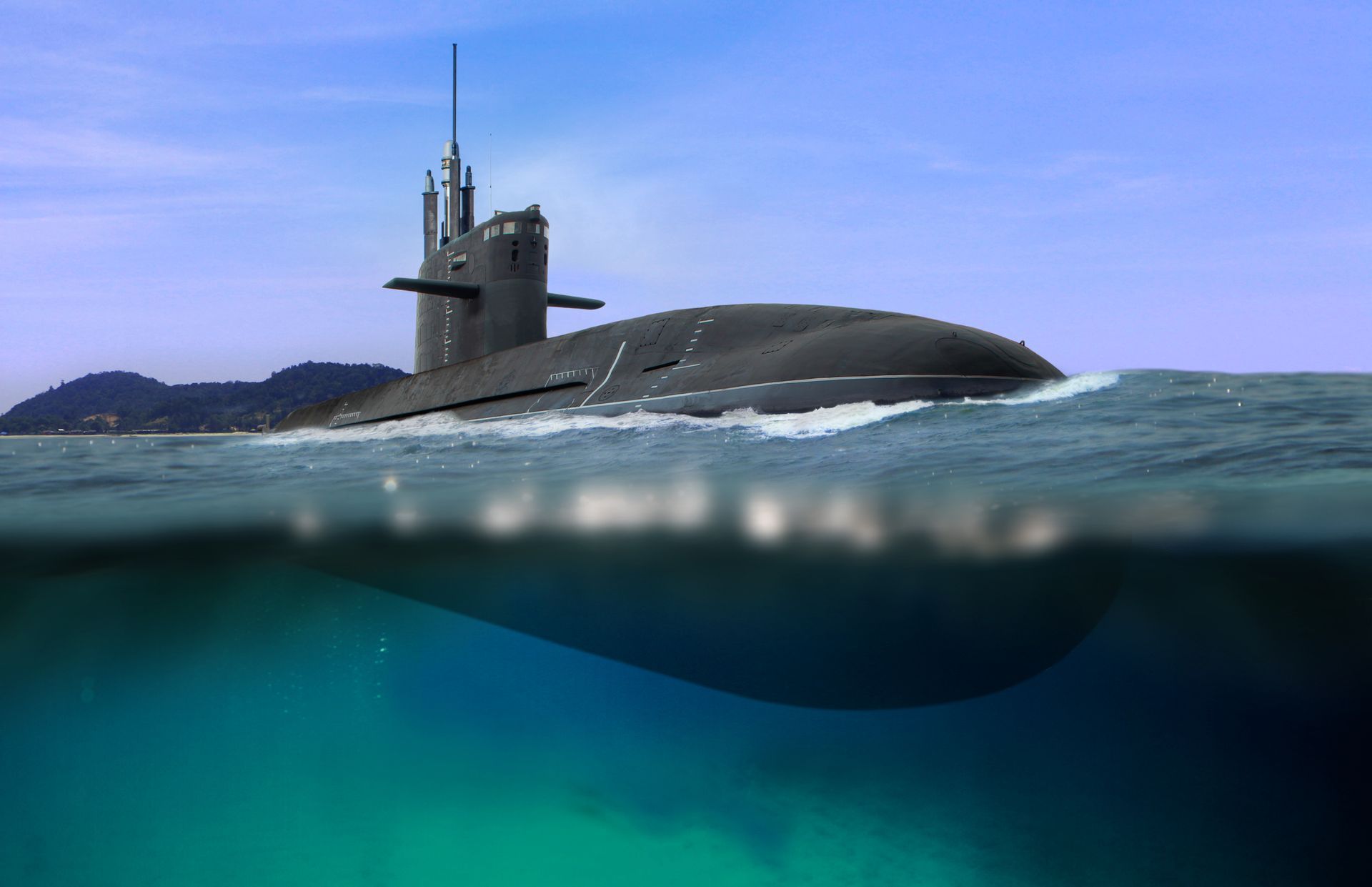

Corrosion Protection

Hayden's technicians have applied corrosion-resistant coatings to bridges, ships, sculptures, and more. Most corrosion barriers are designed to be self-sacrificing, oxidizing more readily than the surfaces they are protecting.

On-Site Coating Service Application Logistics

Many combustion processes can be performed anywhere, provided bottled acetylene and oxygen, and compressed air, can be located adjacent to the work site. Electric arc wire coatings require a moderate amount of electric power and compressed air or bottled nitrogen. Plasma coatings require industrial electrical service, bottled compressed gasses, compressed air, and cooling water supply and return.

On-Site Field Coating Services

On-Site Traction Coating

Learn more about our On-Site traction Coating Process and Benefits.

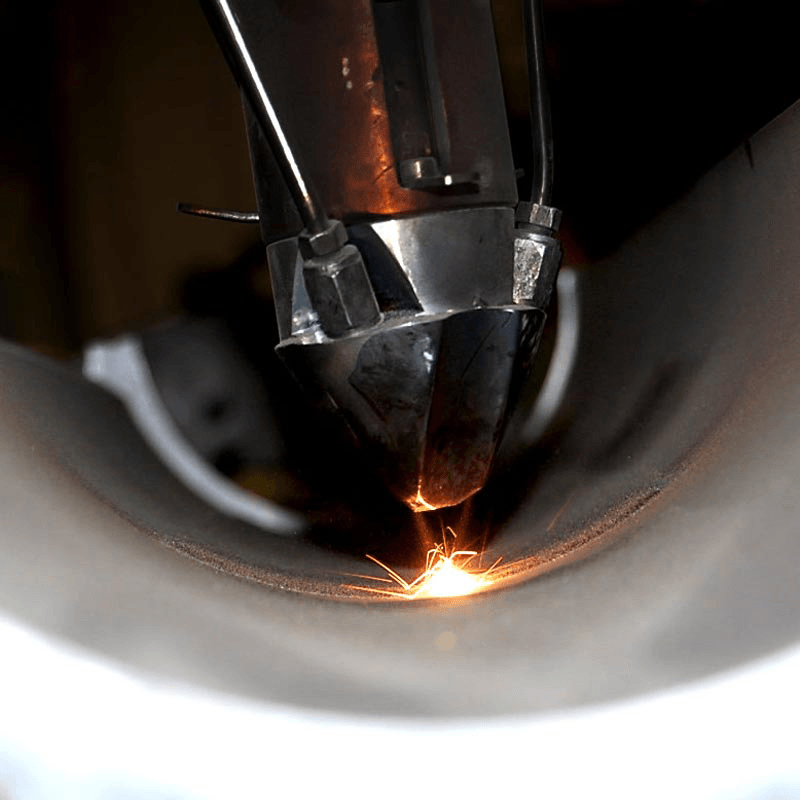

On-Site Laser Cladding

When time is of the essence, a laser clad repair can be done on site and often in place to get your machine back on line quickly and keep it running without risk of failure.

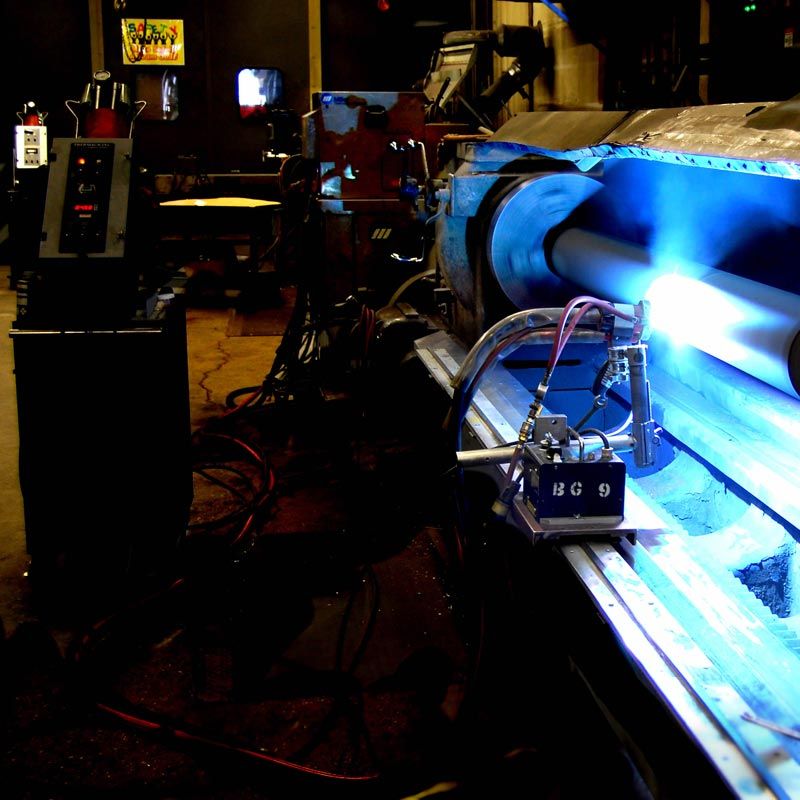

On-Site Plasma Spray Repair

Plasma spraying is capable of applying the broadest array of materials, ranging from pure metals and alloys, to carbides, to ceramics with excellent density and very low impurity.

On-Site Roll Cleaning

Roll cleaning is an on-site service we perform, usually during a shutdown or outage.

On-Site Field Coating Resources

On-Site Field Coating Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

On-Site Quote Request

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU