Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

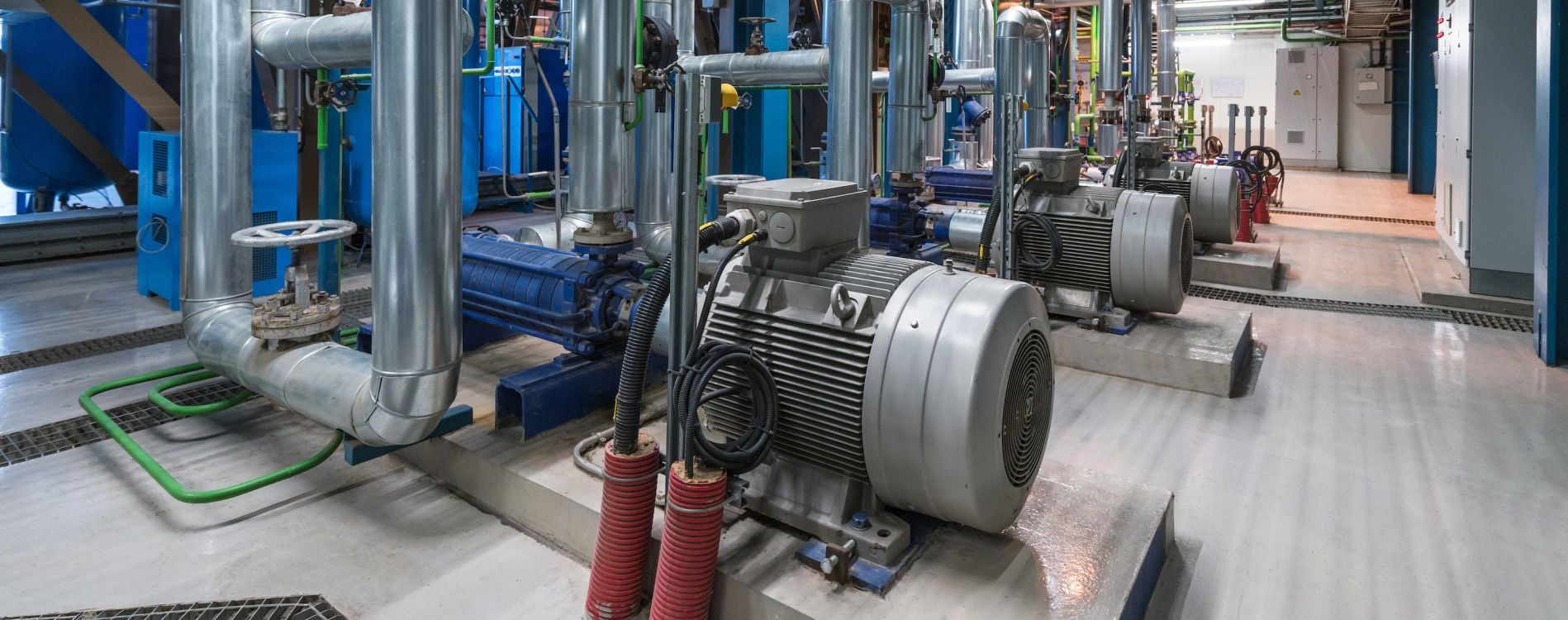

Power Generation - Thermal Spray Coating

Serving the Power Generation community with wear, erosion, thermal barrier coating solutions.

Onsite shaft repair services for Nuclear Maintenance facilities (plasma arc spray on-site)

Industries

Common coating process specification include:

| GE | Ansaldo | PSM | Solar Turbine | Siemens Energy |

|---|---|---|---|---|

| P16B-AG11 | RP.017E | 400-4 | ES1750 | 83336AA |

| P16B-AG3 | RP.0058E | 400-5 | ES9-376 | 83269A4 |

| P16B-AG1 | 402-2 | 83262Y2 | ||

| 402-3 | 83269Z2 | |||

| 410-1 | 83262Z7 | |||

| SiePEC DPTLV-00000472 |

Common parts list specified for coatings include:

Spring Clips

Retainers

Cross Fire Tubes

Transition Piece

Bullhorn Brackets

Labyrinth Seals

Collars

Fuel Nozzle Tips

Shrouds

Abrasive Wear

Piston Rings

Flex Seals

Hula Seals

Combustion Basket

Flame Cylinder

Link pages:

Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

Thermal Spray Quote Request

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU