Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

Photo Gallery

-

Button

The high feedstock capacity of the arc wire system makes it ideal for coating large areas, such as structural surfaces and large rolls.

-

Button

Coatings applied by the HVOF process exhibit density, hardness, and bond strength characteristics that can significantly outperform other methods of application.

-

Button

At Hayden Corporation, we believe that your parts should survive the most extreme services environments.

-

Button

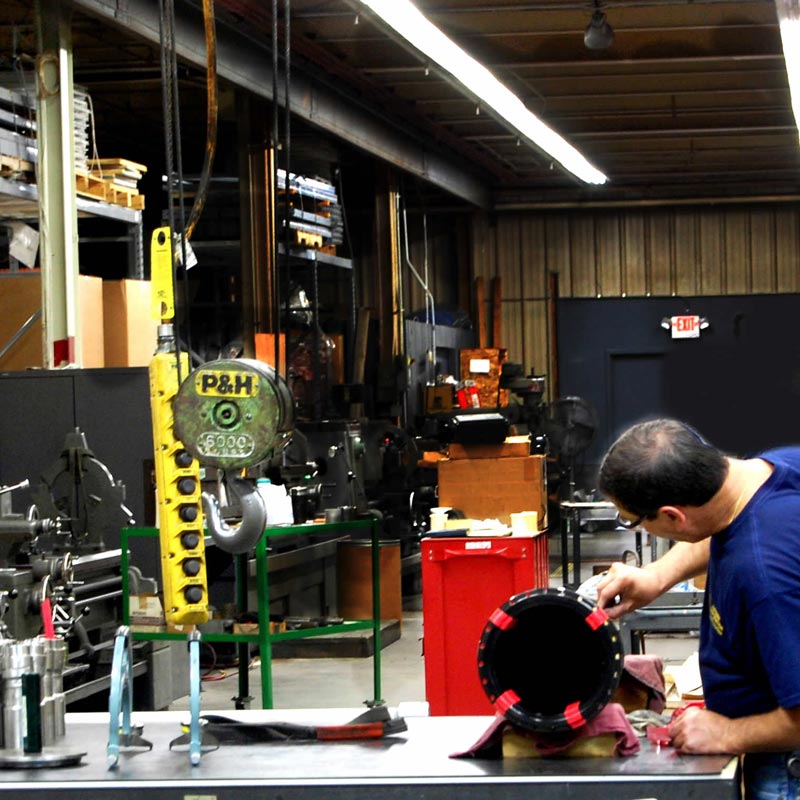

Hadyen supports a full-services, in-house machining division for all wear-resistant coatings.

-

Button

CNC grinding is a critical step in thermal spray processes.

-

Button

Hayden Corp. is a GE-approved vendor, servicing land-based gas turbine parts.

-

Button

Quality assurance is crucial to Hayden Corporation's success. All finished work is reviewed in a thorough inspection process.

-

Button

Twin arc wire spraying of zinc onto a polyurethane component.

-

Button

Twin arc wire spraying of ultrahard micromatrix steel composite.

-

Button

Technician abrasive blasting a large feed screw in our large blast room.

-

Button

Welders fusing nickel chrome alloy onto a stainless steel component.

-

Button

Flame spraying of tin wire onto a housing for electrical grounding.

-

Button

Closeup of cross section of a nickel chrome boron self fluxing alloy coating.

-

Button

Diamond CNC grinding of chrome oxide ceramic on a flanged shaft.

-

Button

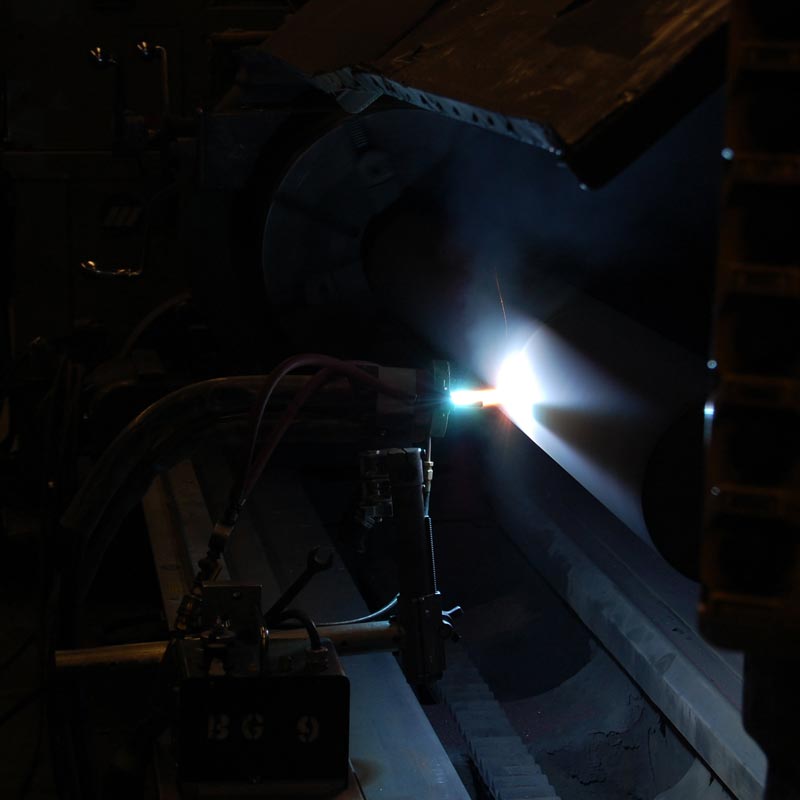

Slick-up phase of fusing a self fluxing alloy coating on a section of shaft stock.

-

Button

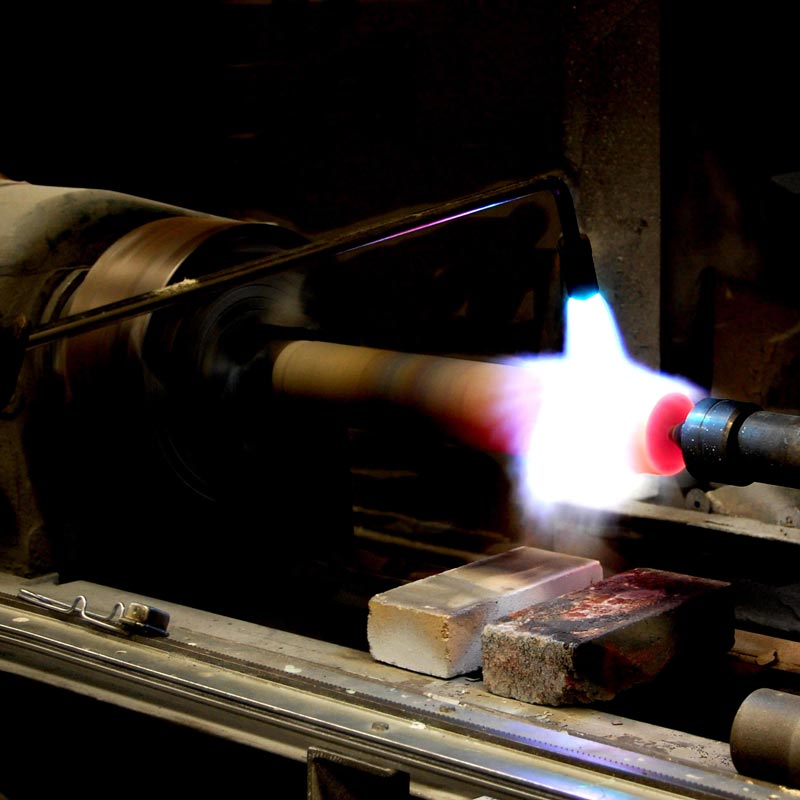

Torch preheating of a self fluxing alloy coating on a section of shaft stock.

-

Button

Machinist monitoring the progress of a CNC grinding operation.

-

Button

Completed grinding of chrome oxide ceramic on flanged shafts.

-

Button

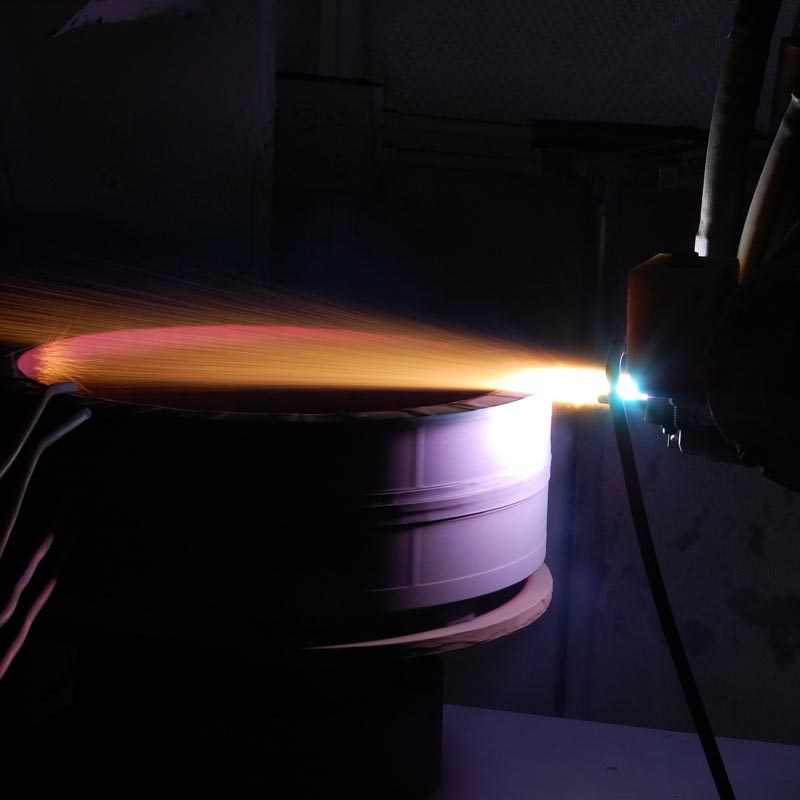

Plasma application of tungsten carbide to a roll face.

-

Button

Hayden Corporation can deploy field teams to apply our thermal sprayed coatings on-site.

-

Button

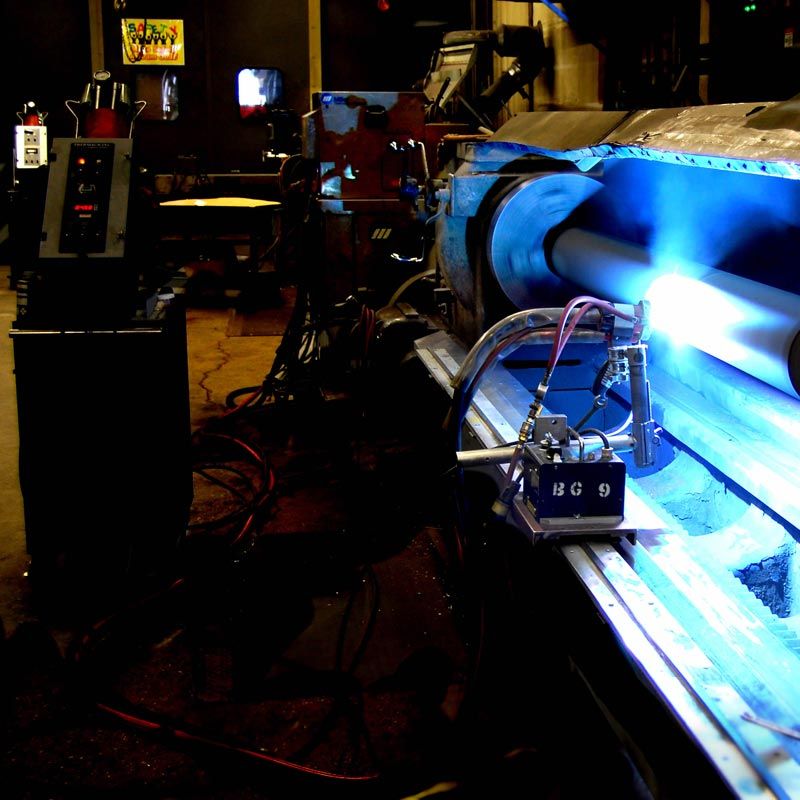

Plasma application of chrome oxide to a large shaft OD.

-

Button

Plasma application of nickel aluminide to a sleeve.

-

Button

Inspector performing final inspection, using snap gauges and micrometers.

-

Button

Ceramic coated cylinders lined up for final inspection.

-

Button

Technician logging physical testing information in our metallurgical lab.

-

Button

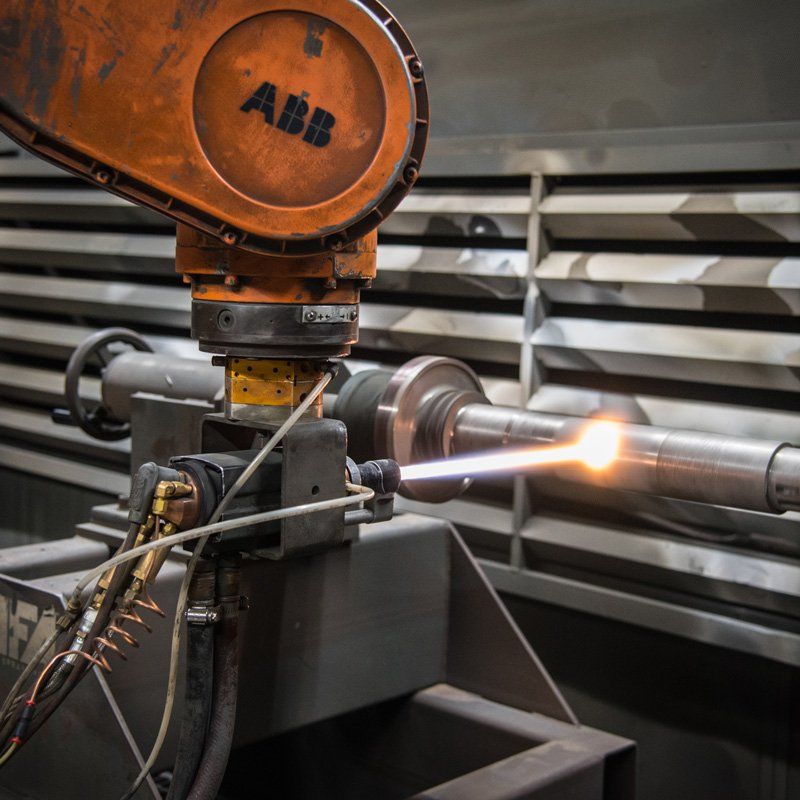

Automated HVOF application of tungsten carbide using Stellite JetKote equipment.

-

Button

Manual application of shielded metal arc welding.

-

Button

Technician applying thermal sprayed aluminum to a customer component at their facility.

Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

Gallery Quote Request

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU