Laser Hardening

Laser Hardening - Precision Control for Sensitive Applications

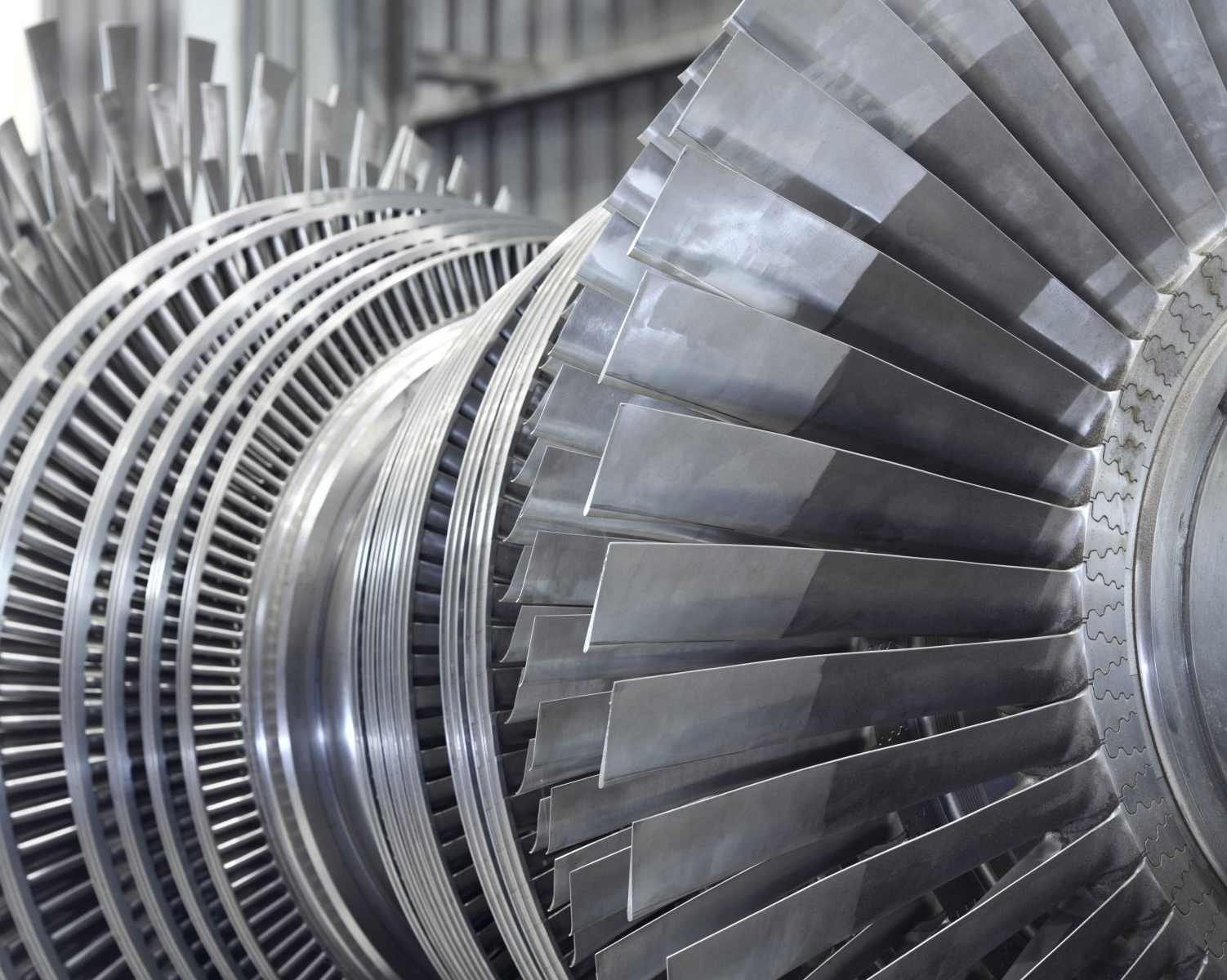

Laser hardening is an alternative to furnace or flame hardening for heat treatable metals. Some stainless and carbon steels, nickel alloys, and other materials can undergo structural changes when heat is applied for a specific time and temperature. These changes typically cause the material to become harder, and, because the transformation happens from the surface where the heat is applied, the internal portions of a heat-treated component can remain softer and more ductile.

Laser Hardening Practice

Laser hardening replaces heat treating methods that typically affect the whole surface of the part (furnace heat treating) or a large portion of it (flame hardening), allowing only the specific areas exposed to the laser beam to be hardened. Laser heat treating also allows for exacting control of the heat input to the treated surface by varying the laser power and the speed with which the heat is applied. The result is that hardening is achieved where it is needed, and the part retains its natural strength and ductility where it is not.

Laser Hardening Applications

Firearms

Mechanical components most susceptible to wear, such as hammers and slides, are often manufactured from tough and durable high performance corrosion resistant alloys. These materials are often well suited to heat treating, which can substantially extend service life, fit, and action without adversely affecting ruggedness and durability.

Laser Hardening Application Criteria

Laser hardening requires parts to be manufactured from heat treatable, hardenable alloys such as 400-series stainless steel, Inconel, or high carbon steel. The time and temperature curves of these materials will dictate the range of hardness achievable by heat treating, and, for low-distortion applications, it is prudent to select a target hardness somewhat below the maximum achievable. Unlike furnace or flame hardening, laser hardening is a line of sight process, and so the surface to be treated must be directly visible. Unlike laser cladding, standoff is not critical; even deep surfaces can be hardened, provided there is a direct line of sight.

Laser Hardening Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

Laser Hardening Quote Request

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.