Full-Service Supplier of Thermal Spray Coating, Laser Cladding, and Machining

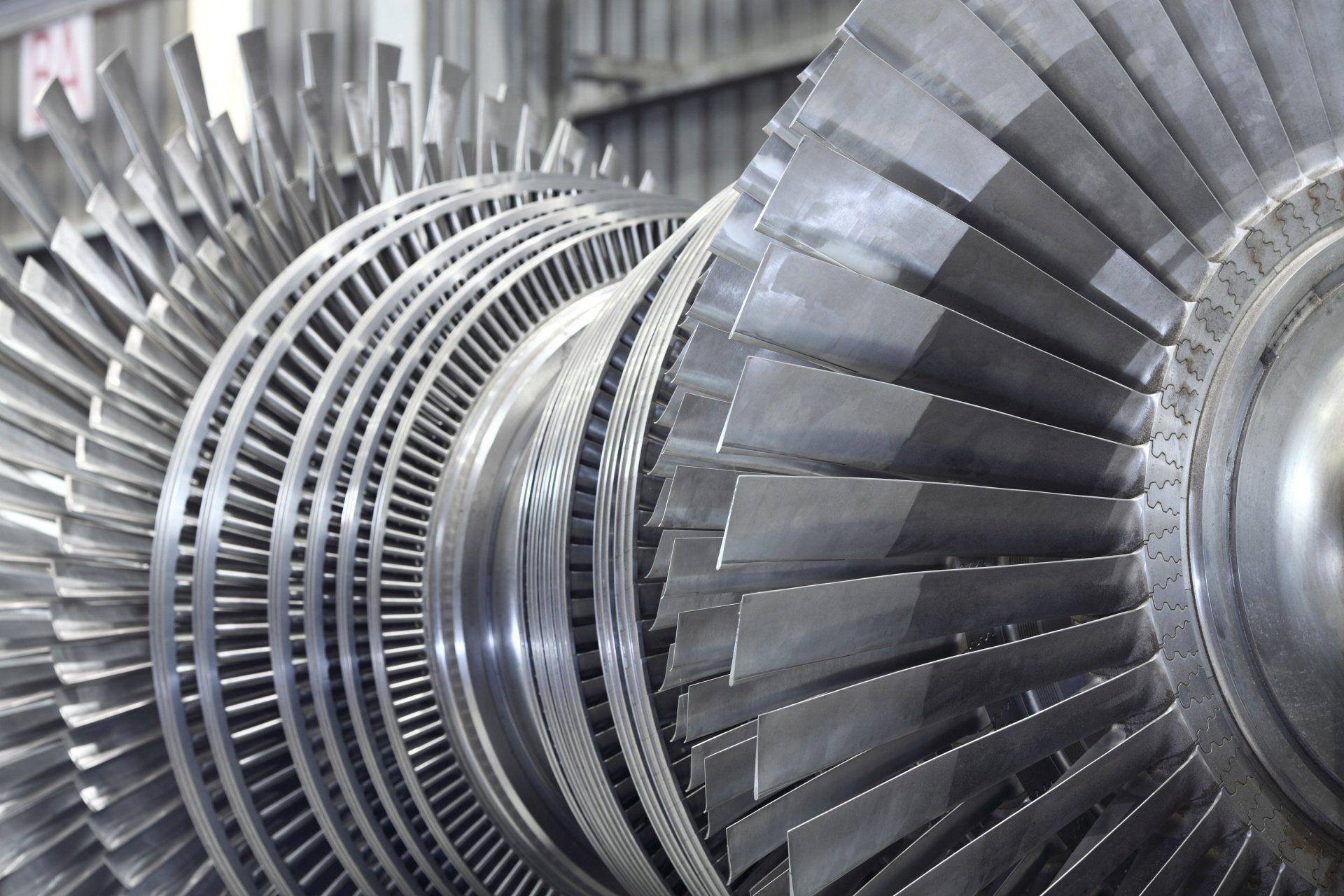

Cutting-edge coatings provide precise protection for complex machinery, ensuring a perfect fit in the tightest of spaces. More commonly used in aircraft and land-based gas turbine engines and similar environments requiring tight mechanical clearance between moving and non-moving parts, an abradable coating can be applied to one of two surfaces which, by its design, must move freely with a minimum of clearance against a stationary mating surface. The mating surface is often coated with a wear-resistant carbide coating.

In turbine applications, these coatings permit rotary shaft seals to move freely while minimizing the flow of gas around, rather than through, the rotating elements. This ensures the maximum transfer of energy to the output torque. As these parts operate, the friction between the coated surfaces will cause the abradable material to wear just enough to permit free motion. The result is a precision fit between the two surfaces, generous enough to allow unrestricted movement but small enough to prevent most materials from passing through. This clearance control provides more efficient operation and extended service life for the machinery.

Common Parts and Applications

Thermal spray coatings are commonly used in a variety of parts and applications that require a precision fit between two surfaces. Some common parts and applications include:

- Piston rings, valves, and valve seats

- Gas turbine engines

- Shaft seals and bearings

- Compressors

- Aerospace components

- Mining equipment

- Exhaust systems in automotive and marine applications.

Hayden Corp recommends aluminum graphite, aluminum polyester, and nickel graphite for this application. View our

thermal spray materials guide for more details

Extend the Life of Your Parts and Equipment with Thermal Spray Coatings

Thermal spray coatings are an ideal solution for components that require precise clearance control. They help extend the life of your parts and equipment, even in situations where extreme temperatures, pressure, and friction are present. With the help of thermal spray coatings, you can ensure your complex machinery runs at peak efficiency for as long as possible!

For more information about how

thermal spray coatings can benefit your applications,

contact Hayden Corp in West Springfield, MA. With over 100 years of experience in the industry, we will be happy to discuss your project and answer any questions you may have.

Contact us today to get started!

Applications

Request an Online Quote

Complete our online quote request form below.

We will contact you within the same business day.

Clearance Control Quote Request

We will get back to you as soon as possible.

Please try again later.

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.

Tough Coatings for Harsh Environments

The Northeast's only full-service supplier of thermal spray coating, hardface welding, and machining. Your application is tough - and your market is even tougher. Our solutions-based expert team of craftsmen and technicians know the best solutions that affect your parts.

MENU