High Velocity Oxygen Fuel (HVOF) Coating

HVOF High Velocity Oxygen Fuel Spraying

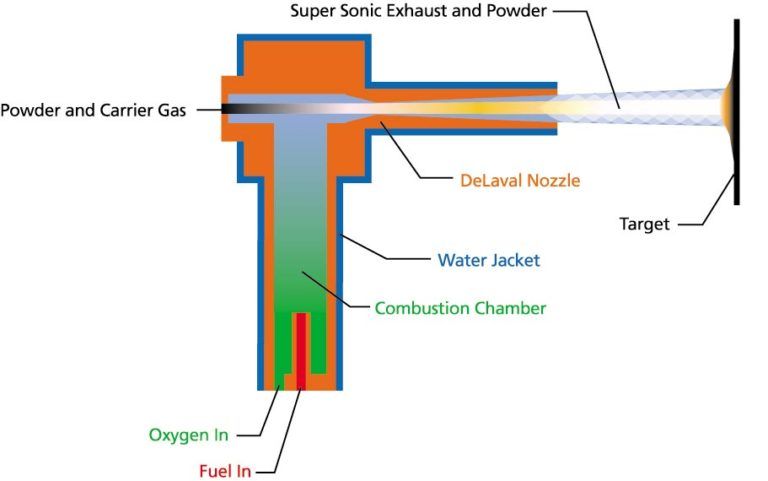

HVOF is a high velocity thermal spraying process that produces coatings with excellent adhesion and wear resistance. It is often used to coat components in the aerospace and petroleum industries. The combustion process uses specially designed nozzles to accelerate the exhaust gases to supersonic velocities, much like a military fighter plane’s engine in afterburner. Powdered coating material is injected into the high velocity gas stream and is accelerated toward the target surface.The coating is deposited with substantial energy and exceptional density and bond strength.

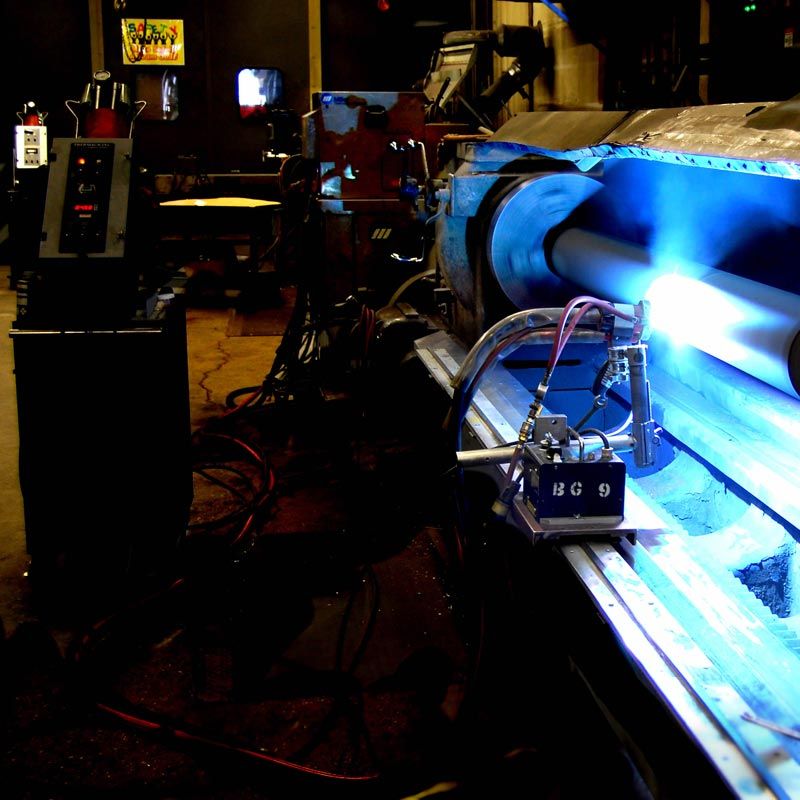

HVOF coatings are typically high-hardness materials such as tungsten carbide, chromium carbide, or other metals. HVOF-applied Tungsten carbide coatings are the hardest and most wear-resistant, while chromium carbide coatings offer wear resistance at high temperatures. Coatings applied by the High-Velocity Oxy-Fuel process exhibit density, hardness, and bond strength characteristics that can significantly outperform other methods of application and can significantly increase wear resistance and increase erosion protection. In most cases, spraying is performed in fully automated robotic coating cells for high accuracy and repeatability.

To ensure optimal HVOF coating adhesion and performance, it is important to use high-quality substrate materials that have been properly prepared. Surface defects should be kept to a minimum, and any contaminants must be removed before coating. Hayden Corp can assist you in developing your application.

HVOF coatings can be applied to a variety of substrates, including metals and composites. HVOF is often used to coat turbine blades, bearings, and other components that are subject to high levels of wear and tear.

HVOF Coating Method

Every thermal spray coating process requires a method of propelling the sprayed material onto the work surface. The essential feature of a thermal sprayed coating is that the particles sprayed, upon impact with the work, must deform enough to mechanically lock into the profile of the surface they impact. Initially, thermal spray technology centered around techniques of heating the particles into plasticity before impact to guarantee adequate deformation. HVOF introduced a new method.

By using a small combustion chamber to generate extreme (essentially supersonic) exhaust velocities, powdered material injected into this focused exhaust stream is imparted with enough velocity that the force of the impact alone is virtually enough to achieve adequate bonding. The kinetic energy of the particles is so great, in fact, that most porosity typical in a traditionally applied coating is essentially hammered out. Low-porosity, denser coatings wear better and can provide more protection per thousandth of an inch applied.

HVOF Coating Practice

The HVOF (high velocity oxygen fuel) process uses high volumes of gas flow and tends to be used for the application of high-value, high performance coatings such as tungsten carbide and cobalt superalloys. For this reason, an HVOF-applied coating will typically cost more than a plasma spray application of the same material. Additionally, the higher velocities of the HVOF stream tend to remove typical masking materials, and customized hard masking is often required.

Work setup and operating parameters are key in optimizing the performance of an HVOF coating. Hayden’s role as a service and support facility for several industries requires our staff to have exceptional abilities in creating effective procedures for a wide variety of materials on parts of all geometries.

AS9100-certified

process control guarantees that each procedure will be monitored for quality and will be repeatable from batch to batch.

Benefits of HVOF Thermal Spray Coatings

There are a few benefits that make HVOF coatings the ideal choice for many applications.

- HVOF spray coatings are dense, meaning they have very low porosity. This makes them more wear-resistant and less likely to chip or flake off. They also have a very high bond strength, which means they are less likely to come loose over time.

- The HVOF thermal spray coating process is applied at a much higher pressures than other thermal spray coatings, which allows them to better bond to the substrate.

- HVOF thermal spraying can be applied to a variety of different materials, including metals and composites.

- HVOF thermal spray coatings have a very smooth and consistent surface finish. This makes them ideal for applications where a smooth surface is necessary, such as in bearings and turbine blades.

HVOF High Velocity Oxygen Fuel Frequently Asked Questions

Request HVOF Coatings & Services

Hayden Corp is a leading provider of HVOF thermal spray coatings. We offer a wide range of HVOF services including hard chrome replacement,

roll surfacing, cutting edges,

turbine blades, bearings, and wear surfaces.

Contact us today

to learn more about our HVOF capabilities or to

request a quote.

HVOF Resources

Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

HVOF Quote Request

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.