Our Focus is on Quality & Flexibility

We stake our reputation on long-standing

thermal spray coating expertise. Our customers turn to us as their strategic thermal spray partner because of our focus on flexibility and quality.

Flexibility

Flexibility is a key strength to look for in your thermal spray coatings partner. Hayden Corp. offers the flexibility to handle large parts or small, in high volume, small batches, or one-offs.

Our handling capacity — up to 6 tons, 72” diameter, and 400” length — is broad, as is our diverse material inventory of 300-plus active materials ready for thermal spray coating application.

Whether your components require HP-HVOF, HVOF, Plasma Spray, Arc Wire, Flame Powder, or Flame Wire thermal spray coatings, we can handle it. Additionally, our multi-process cells for plasma, HVOF, and arc wire application allow us to complete this work consistently and repeatably in high volume.

Quality

At Hayden Corp., quality is an intent built into the way we treat our customers and their components, from job start to finish.

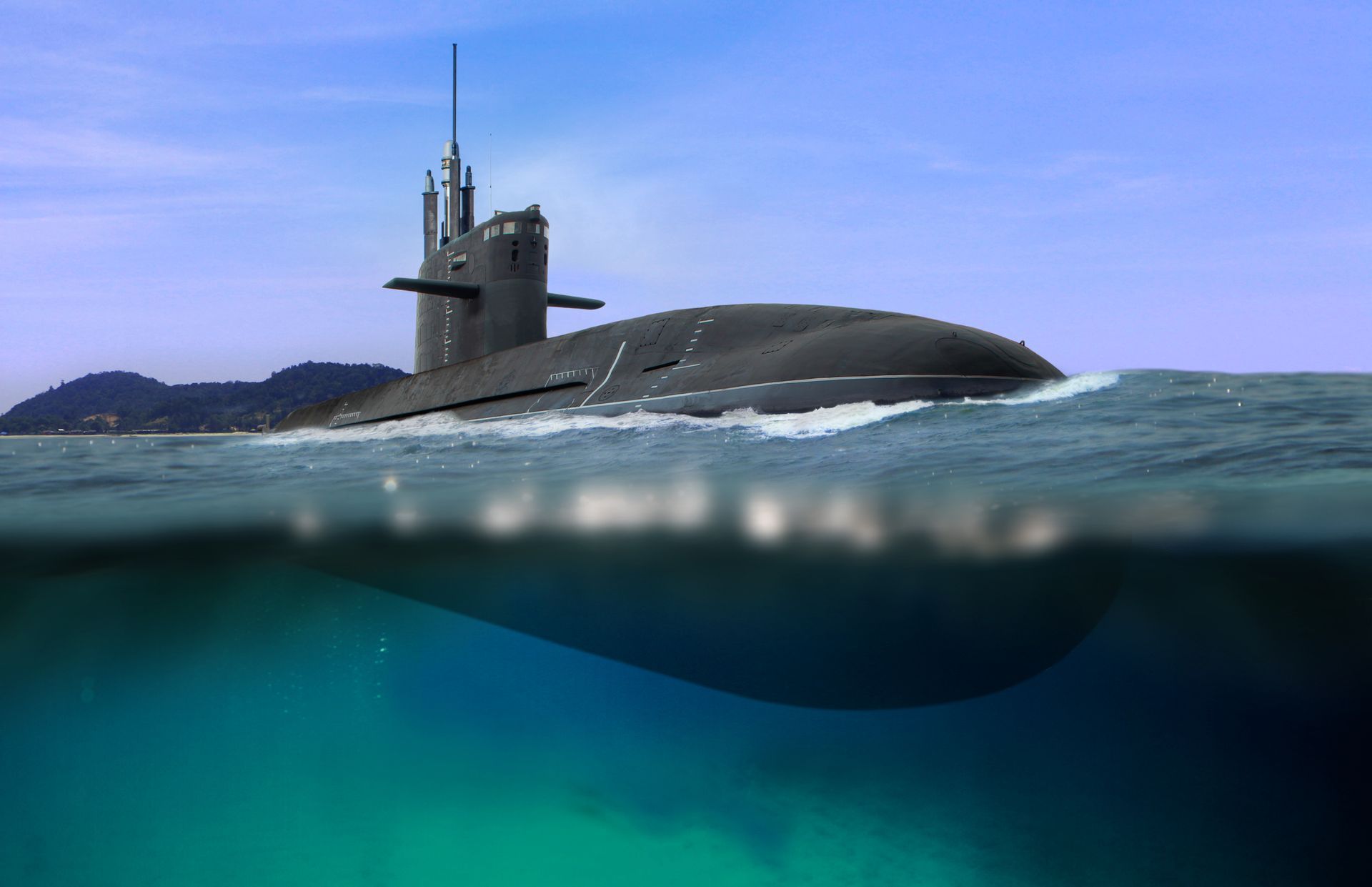

Customer service is part of that quality experience. We want you to turn to us as the experts when you have questions. Not sure which thermal spray coating application is best for your component and the wear problems it will experience? Our sales engineers will advise you. Need to meet strict military or commercial specifications? Our technicians are also certified for a variety of specialized applications for both military and commercial OEMs.

Our Process

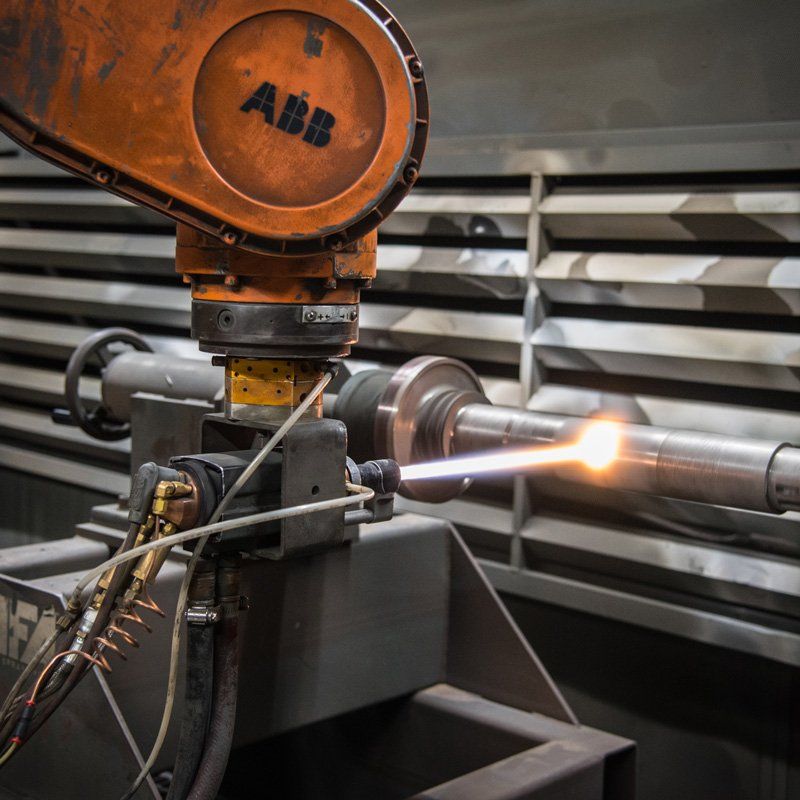

Hayden Corporation plans automation into nearly every job. Robotic application of thermal spray coatings minimizes human error and inconsistency, allowing us to approach each component with utmost flexibility, repeatability, and accuracy.

We strive to be a turnkey, high quality solution for our customers. Our on-site metallurgical lab team has a full complement of physical testing capabilities. We also complete in-house machining and finishing, including CNC grinding and superfinishing, reducing lead time and improving quality by eliminating outside subcontract operations.

Thermal Spray Coating Services

HVOF

Coatings applied by the HVOF process exhibit density, hardness, and bond strength characteristics that can significantly outperform other methods of application.

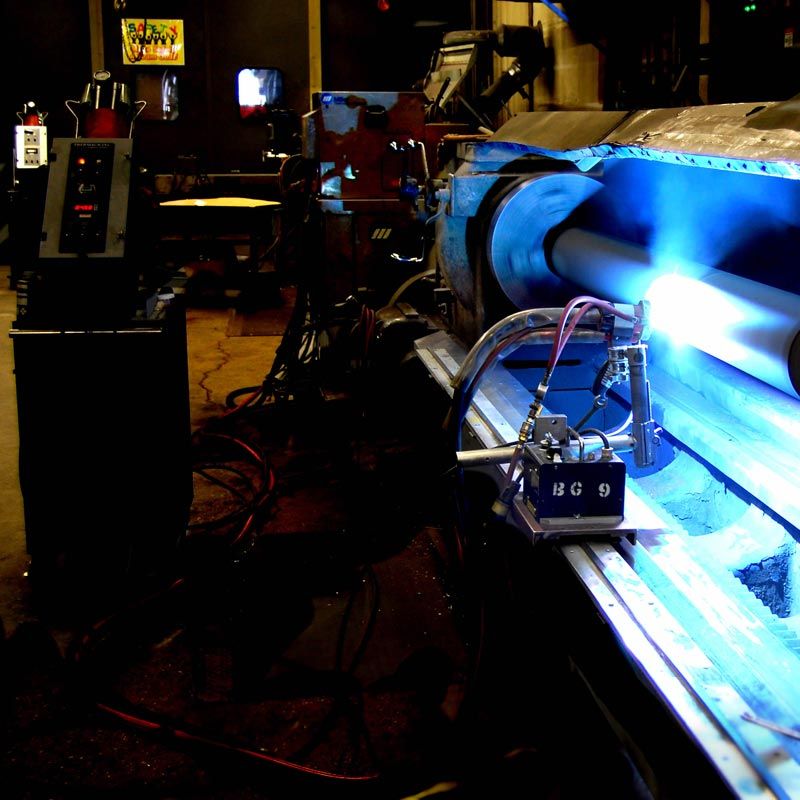

Flame Spray & Arc-Wire

Flame spray and arc wire applications are highly portable and easily deployed in the field, on-site at our customers’ facilities. Time tested and economical, these thermal spray coatings excel in large-scale projects.

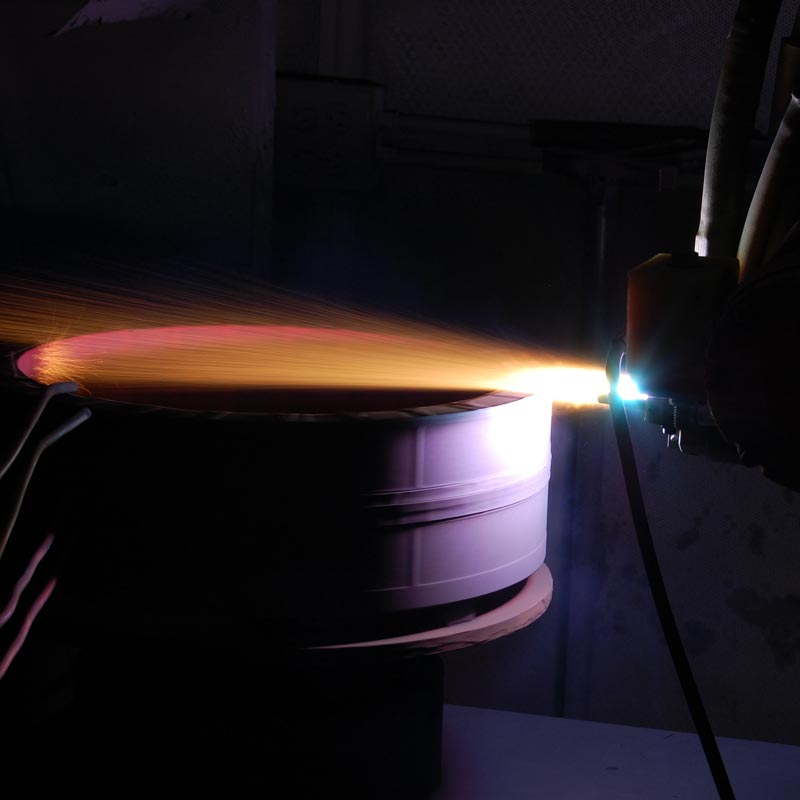

Plasma

Plasma sprayed coatings include the broadest range of materials, from soft metals like copper and iron, to carbides, to super hard high-melting-point ceramics.

Thermal Spray Coating Information & Frequently Asked Questions

Thermal Spray Coating Experts

With over 100 years of experience, Hayden Corp has established itself as an industry leader in thermal spray coatings and other cutting edge finishing technologies. With our advanced thermal spray coating systems and unparalleled expertise, we have become a go-to source for everything from thermal barrier coatings to corrosion protection. Whether you are looking for effective coating solutions for a new product line or need help maintaining your existing equipment over time, Hayden Corp has the experience, expertise, and resources needed to exceed your expectations.

Thermal Spray Coating Resources

Thermal Spray Coating Gallery

Thermal Spray Coating Quote

Searching for thermal spray companies near me? Contact Hayden Corp Today!

Complete our online quote request form below.

We will contact you within the same business day.

Thermal Spray Quote Request

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.