Laser Cladding Services

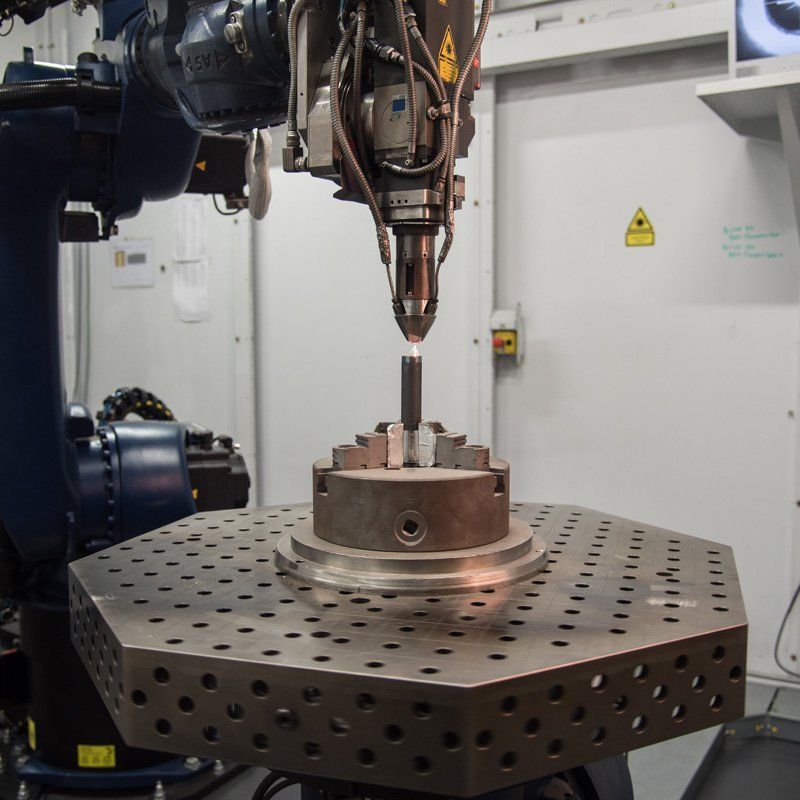

Fully Automated Laser Cladding

All laser cladding operations by Hayden Corp. are fully automated, ensuring accurate and repeatable applications of the weld overlay. This ensures that the weld is deposited evenly and smoothly, with no gaps or voids. The result is a stronger, more consistent bond that can withstand high temperatures and extreme conditions. Hayden's laser cladding services are the perfect solution for those who need precise, durable protection.

Common Applications Include:

Laser cladding is a process that can be used to improve the surface properties of a wide range of materials. Common laser cladding applications include:

- Improving the wear resistance of tools and components subject to high levels of friction and abrasion

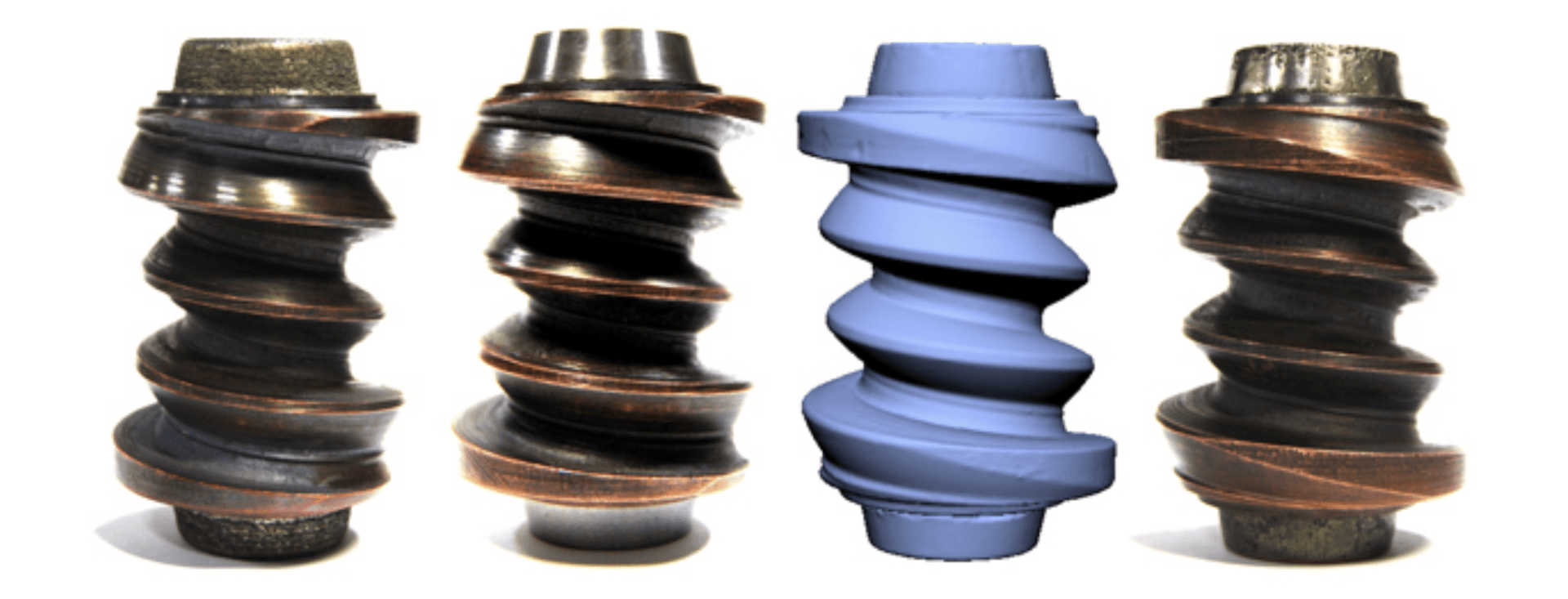

- Restoring the original dimensions of worn parts

- Repairing surface defects such as cracks, cavities, and corrosion damage

- Applying hardfacing alloys to increase the service life of components exposed to extreme conditions

- Applying specialty coatings for improved electrical or thermal conductivity, tribological performance, or other specific properties

Laser Cladding Process

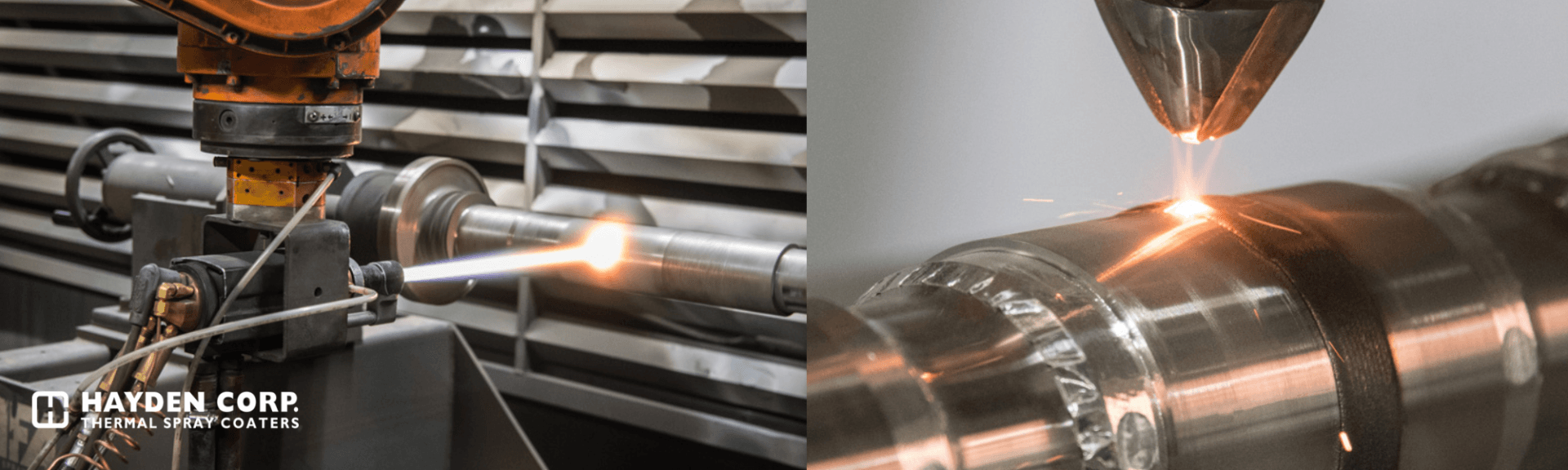

Advancements in laser material processing have virtually removed much of the risk of applying fully-fused metallic overlays, even to complex and highly-machined components. Laser cladding allows the extremely high heat of weld fusion to be contained to a small local surface area, and with minimal penetration of the heat into the substrate. The process, variously referred to as laser cladding, laser hardfacing, and direct metal deposition (DMD or LMD), uses a high-powered industrial laser, with beam guidance controlled by a precision CNC machine tool to create patterns of hardface welding beads wherever needed on the surface of metallic components.

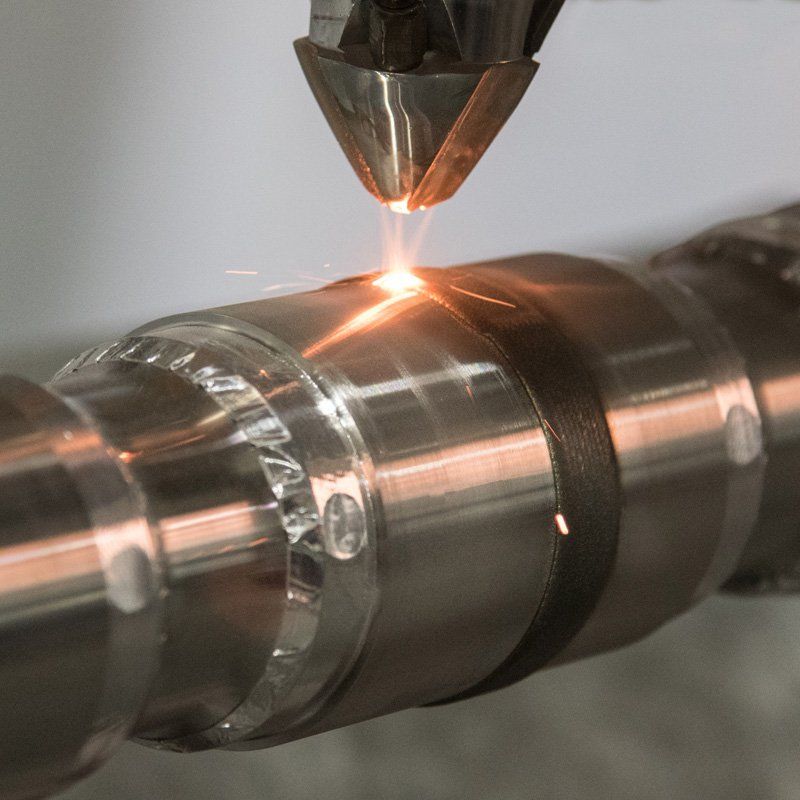

The machine tool steers the focused laser beam, in concert with a means for injecting powdered hardfacing material, over the workpiece so that the laser can melt and alloy the surface with the deposited metal. The result is a welded overlay of hardfaced material precisely applied where it is needed, using only the amount of laser energy necessary to create a high-integrity weld bead.

Laser application of metallic overlays to metallic substrates offers properties similar to overlays applied by traditional welding methods but with substrate/overlay metallurgy effects more akin to sprayed and fused coatings. The result is a true metallurgical bond of overlay and substrate with minimal dilution and a low heat-affected zone (HAZ) thickness. Laser-applied overlays do not require masking for precise deposit geometry, and they can be tailored to nearly any substrate/overlay pairing.

Laser Cladding Method

Laser-applied overlays are produced by locally heating the substrate metal to a molten state using a tightly controlled beam of laser energy and then introducing the overlay material in powder or wire form. The melt pool produced by the defocused laser beam absorbs the melted feedstock, and, as the beam and powder injection are moved away, the material rapidly solidifies, producing a fully dense weld bead. The welding apparatus is attached to a motion control system—either a five-axis CNC device or a six-axis robotic arm—which can be programmed to precisely guide the tool over complex surfaces, yielding a uniform overlay thickness over nearly any outer surface geometry. Monitoring of the tool speed over the surface allows the system to accurately throttle laser power and powder parameters to ensure uniform coating properties despite acceleration and deceleration of the tool by the motion control system.

Laser Cladding Practice

Due to the precise control of the laser energy at the weld pool, laser cladding overlays can be tailored to provide optimal deposition efficiency, thickness, and/or HAZ. Typical single-pass thicknesses can be in the range of .015” to .060”, though other dimensions are possible. Geometric accuracy of the overlay’s dimensions can be within a few thousandths of an inch, depending on the shape of the weld border. Post-processing such as grinding or polishing can be used to control the surface finish of the overlay after application.

Laser Cladding Frequently Asked Questions

Request Laser Cladding Services

Hayden Corporation offers laser cladding services to manufacturers and end users nationwide. We are a leading provider of hardfacing and

thermal spray coating services, and our experienced team can apply a wide range of materials using the latest laser cladding technology. If you would like to learn more about our laser cladding services, or if you need assistance selecting the right material for your application, please contact us today. We will be happy to answer any questions you may have and provide a free quote for your project.

Laser Cladding Resources

Online Quote Request

Complete our online quote request form below.

We will contact you within the same business day.

Laser Cladding Quote

Contact Hayden Corp.

Have a question or have a specific need? Contact our main office or send us a message online.