Thermal Spray Coating & Laser Cladding Services in New Jersey

Our expert team of craftsmen and technicians that serve New Jersey know the best solutions to the greatest abrasion, adhesion, corrosion, heat, and other wear problems affecting your parts.

Extreme Flexibility for Extreme Projects in NJ

Your application is tough - and your market is even tougher. Rugged, harsh service environments demand optimal performance from all machinery and parts. At Hayden Corporation, we believe that your parts should survive the most extreme environments. Hayden Corporation Thermal Spray Coaters offers Thermal Spray Coating & Laser Cladding services throughout

New Jersey.

Free Quote Request

Submit your information below

New Jersey

New Jersey Thermal Spray Coating & Laser Cladding Experts

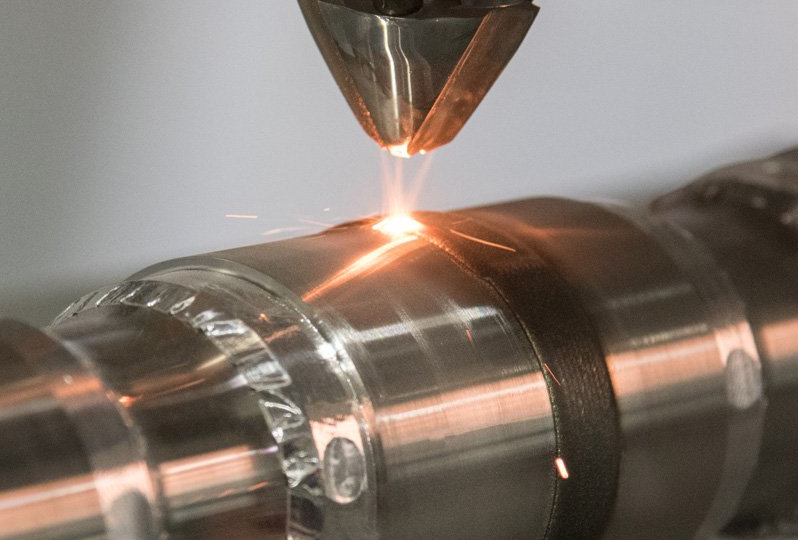

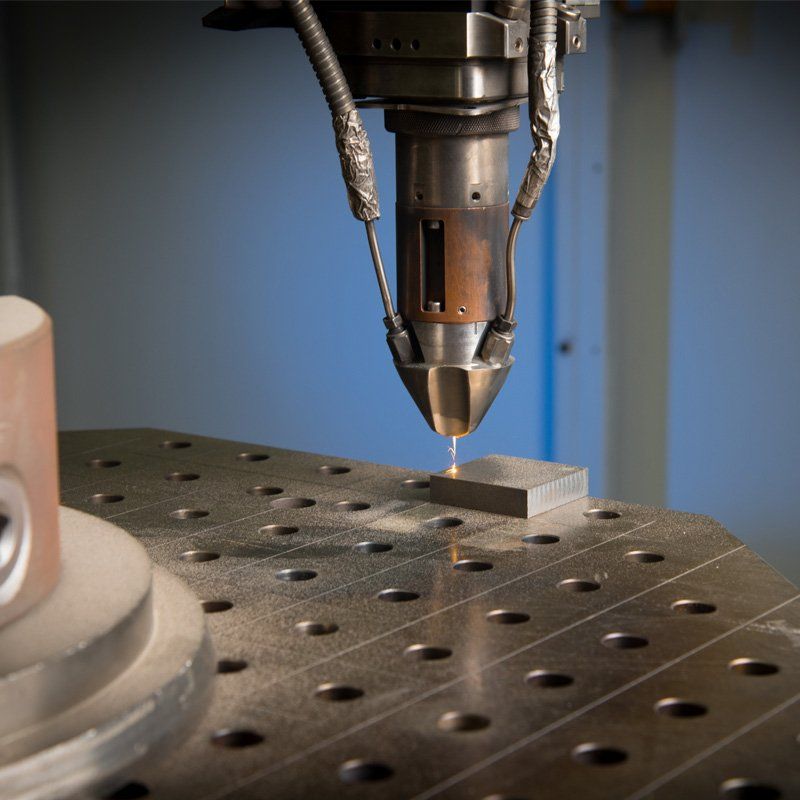

In many industries, parts are exposed to extremely high temperatures, corrosive substances, or other harsh conditions. Over time, these conditions can cause wear and tear that significantly reduces the lifespan of the part. To extend the life of your parts and improve their performance in rugged service environments, consider thermal spray coating or laser cladding services from Hayden Corporation. Thermal spray coating is a process in which a layer of material is applied to the surface of a part using high-temperature flames. This process creates a barrier that protects the part from corrosion, abrasion, and other forms of wear and tear. Laser cladding is a similar process, but it uses a laser beam to apply the coating material. This process is often used for parts that require a very thin coating. If you're not sure which process is right for your needs, our team at Hayden Corporation will be happy to help you find the best solution. We offer both thermal spray coating and laser cladding services throughout New Jersey.

Hayden Corp is dedicated to providing quality thermal spray coating and laser cladding services that meet the specific needs of each customer. Our highly trained and experienced staff use the latest technology and equipment to provide superior services. Hayden Corp's thermal spray coating and laser cladding services are available for a wide variety of applications including, but not limited to:

Thermal Spray Coating Services in New Jersey

At Hayden Corporation, founded in 1919, we stake our reputation on long-standing thermal spray coating expertise. This is especially true in the state of New Jersey, where we have completed numerous projects for clients in a wide range of industries. We understand that each application presents unique challenges, which is why we offer an array of thermal spray coating services to meet the specific needs of each customer.

HVOF Coating in NJ (High Velocity Oxygen Fuel)

Coatings applied by the High-Velocity Oxy-Fuel process, or HVOF for short, are designed to provide high bond strength, hardness, and wear resistance on components subjected to severe wear. Common HVOF applications include hard chrome replacement, roll surfacing, cutting edges and wear surfaces.

Flame Spray & Arc Spray Services in New Jersey

Flame and arc spray thermal spray coatings are applied using processes that melt the coating material and propel it onto the surface of the substrate. This results in a highly adherent, dense, and well-bonded coating. Common applications for flame and arc spray coatings include corrosion protection, wear resistance, electrical conductivity, and thermal insulation.

Plasma Coating in NJ

Plasma spray coatings are applied using equipment that ionizes a gas to form plasma, which is then used to melt and propel the coating material onto the surface of the substrate. This results in a highly adherent, dense, and well-bonded coating. In addition to applications common to other processes, plasma spraying can apply very high melting point materials, like ceramics, and achieves denser, harder wearing surfaces than other conventional methods.

Spray and Fuse Coatings in New Jersey

Spray and fuse thermal spray coatings have been developed to perform at their peak after having undergone an intense fusing stage. Fusing allows for the metals to form a stronger bond, wetting into the surface of the substrate. The end result is a thermal spray coating that is tougher and more corrosion resistant than any other thermal spray process.

Laser Cladding Services in New Jersey

Hayden Corporation's laser cladding capabilities in New Jersey are among the best in the country. We're able to provide fully automated laser deposition for your component repair and OEM needs. Laser cladding is a process whereby a laser is used to apply coatings, providing precise overlays with excellent edge definition, surface finish, and metallurgical bonding. This allows us to meet the most stringent tolerances and requirements for our customers.

Benefits of Laser Cladding include:

Wear Resistance:

Laser application of high-performance alloys can significantly improve the wear resistance of components.

Corrosion Resistance:

Laser cladding provides an excellent impermeable barrier to corrosion, making it ideal for applications in harsh environments.

Thermal Stability:

Laser-applied coatings can improve the thermal stability of components, making them suitable for use in high-temperature applications.

Laser Cladding & Laser Hardening Services in New Jersey

Laser Cladding

Our laser cladding services department leverages our extensive history in the coating and welding industry with the highest-quality laser processing hardware available. We provide expert laser cladding services, delivering the best-engineered laser cladding solution for your wear and corrosion problem.

Precision 3D Cutting

Precise control of an extremely high-quality laser beam allows fast, accurate cutting of metals up to a quarter of an inch thick. Coupled with a robust five-axis CNC machine tool and a large 3m x 1.5m x 1.5m work envelope, our laser system provides unparalleled cutting flexibility and accuracy.

Laser Hardening

Laser hardening is an alternative to furnace or flame hardening for heat treatable metals.

NJ Thermal Spray Coating

HVOF

Coatings applied by the HVOF process exhibit density, hardness, and bond strength characteristics that can significantly outperform other methods of application.

Flame Spray & Arc-Wire

Flame spray and arc wire applications are highly portable and easily deployed in the field, on-site at our customers’ facilities. Time tested and economical, these thermal spray coatings excel in large-scale projects.

Plasma

Plasma sprayed coatings include the broadest range of materials, from soft metals like copper and iron, to carbides, to super hard high-melting-point ceramics.

Request Thermal Spray Coating Services & Laser Cladding Services in New Jersey

If you are located in New Jersey and are searching for thermal spray companies near me or laser cladding companies near me, Hayden Corporation is here to help. We offer a wide range of thermal spray coating and laser cladding services to meet the specific needs of our customers.

We provide services throughout New Jersey including

Jersey City NJ,

Clifton NJ,

Trenton NJ,

Newark NJ

and surrounding areas.

Contact us

today to request a

free quote.

Have a question or have a specific need? Contact our main office or send us a message online.